What are the different types of cello bags?

There are two types of cello bags:

1. Cast Polypropylene (CPP) - Many people buy “cello” bags made from cast poly propylene, sometimes referred to as CPP. These bags are low priced, sold in retail stores and are generally “made in China”. These bags do not have the tensile strength or the gas, vapor, moisture barriers of bags made from BOPP and Cellophane.

2. Biaxially Oriented Polypropylene (BOPP)

film was developed to replace

cellophane because it has superior physical attributes. Prism Pak sells only BOPP and Cellophane Cello Bags as cellophane bags.

How do I know if it's real cellophane?

There are several ways to tell the difference between a cast polypropylene (CPP) bag and a Biaxially Oriented Polypropylene (BOPP) Cellophane bag.

- First, you can not push your finger through a true BOPP bag. It is strong and stiff. A Cast Polypropylene (CPP) bag will elongate when you push your finger through it. This

tensile property, elongation, will allow CPP to elongate from 550%

to 1,000% of the film thickness.

The resultant bag will have a elongation dimple as in this picture.

2. You

can heat seal a Cello Bag with an iron and it will not melt as easily

as a CPP bag. The film is annealed in the manufacturing process which

gives the film high temperature stability. Try this with your Cello Bag

only if you know it is a true cello bag. If you aren't sure, don't try it because CPP bags will melt on you iron very easily .

3. All of the bags can be heated sealed with a regular iron or a industrial Impulse Sealer shown in this picture.

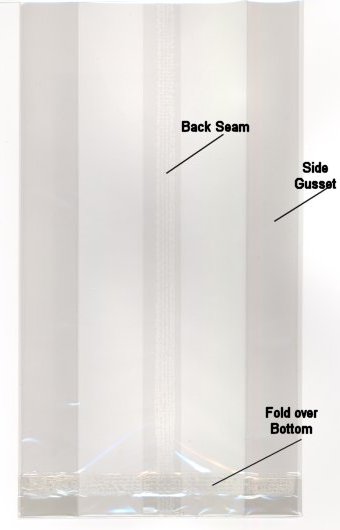

4. All “True Cello Bags”

have a back seam. The back seam is an overlap seam typical of the back

seam on snack food bags such as cookie, cracker, potato chip and

peanut bags. Here is an example of a “True Cello Bag” in the square

style with a foldover bottom an easy stand up feature”

5. Depending

on the type of film used in the bag, a stack of bags may have a gold

tint look. The bags are not old or poor quality. What you are looking

at is light diffusion through a stack of bags. If you look at a single

bag, it is clear. The film used in making the bag is "Saran Coated".

If by chance you have "Saran Wrap tm " in your kitchen cupboard, and you pull out the roll, you will notice it has the same color tint as the bags. Why are Biaxially Oriented Polypropylene cellophane bags good?

BOPP, Biaxially Oriented Polyropylene,

is a flexible material derived from melting and biaxially orienting

(stretching on both axis) a polymer called polypropylene. This raw

material is inert and unaffected by most chemical agents occurring in

everyday life. It meets the requirements of the US Food and Drug

Administration and other relevant authorities throughout the world.

Polypropylene contains primarily carbon and hydrogen, and includes no

heavy metals or other environmentally hazardous substances. The process

of biaxially orienting polypropylene, stretching it in the machine

direction and transverse direction, improves the films physical

properties, such as water vapor barrier, stiffness, dimensional

stability, and optics.

The important properties of Biaxially Oriented Polypropylene BOPP are:

- It has a high tensile strength

- It has a high gloss and clarity

- It has good puncture and flex-crack resistance over a wide range of temperatures

- It is a good barrier to water vapor

- It is resistant to oils and greases

- It is not affected by moisture and does not wrinkle or shrink with environmental changes

Cellophane film begins

life as a natural product - wood. The process of converting wood pulp

to film however, is quite complex. First it undergoes a series of

chemical processes to break the pulp down to a viscose liquid.

The

viscose is extruded and then cast along a series of rollers and baths,

during which a softener is often introduced to provide a measurable

amount of strength and flexibility. Chemicals used in the process are

reclaimed and recycled.

Un-coated cellulose films are highly

permeable to water vapor while still providing an excellent barrier to

micro-bacteria, flavors and aromas. They are naturally glossy,

anti-static, and heat-resistant. Many grades of film are, however, coated, in order to refine and control these natural attributes for specific applications and for moisture and aroma barrier.

For more information regarding packaging films, you can go to the web sites of ExxonMobil tm and UCB tm films, the largest producers of packaging films in the world

Keep your food products tasting “fresh from the oven” delicious...

Breads Snack Cakes Soft Cookies Crispy Cookies Crackers

Our

cello bags are designed to keep baked products looking, smelling and

tasting fresher longer. Our specially formulated cello bags provide

exceptional barrier protection from odors, oxygen and moisture so your

product’s unique taste, texture and aroma are locked in.

The

best way to deliver “bake day” freshness to your customers is to ensure

that your product is equally protected from flavor loss and foreign

odor pickup. The barrier provided by our cello bags is the protection

your baked products need. Your customer will experience the same great

taste and texture each and every time they open a package.

If

you struggle with keeping crispy products tasting crunchy and soft

foods remaining moist and “melt in your mouth” delicious, then our

cello bags are your answer thanks to their superior barrier to moisture.

The

transparent high barrier packaging films for extended shelf life and

appeal promotion on the shelf, have been developed specifically for the

bakery market. These BOPP films include a differentially coated version

- a unique acrylic coating on one side and a very high barrier saran

coating on the other. The film enables food packers to achieve

extremely high levels of prolonged product protection.

|